Casters are essential components in a wide range of industrial and commercial applications, enabling the easy movement of heavy loads. Among the various types of casters available, low center of gravity casters are gaining increasing popularity due to their exceptional stability and performance in high-demand environments. These specialized casters are designed to lower the center of gravity of equipment, making them ideal for applications where stability is paramount.

This article delves into the benefits, features, and key applications of low center of gravity casters, as well as how they can enhance your operations.

What Are Low Center of Gravity Casters?

A low center of gravity caster is a type of caster specifically engineered to ensure that the load it supports remains as stable as possible during movement. By lowering the height at which the load rests, these casters help reduce the risk of tipping, tilting, or unbalanced movement. This is particularly important in environments where safety, precision, and efficiency are critical.

Low center of gravity casters achieve this by using a design that positions the axle closer to the ground compared to standard casters. This adjustment distributes the weight more evenly and makes the caster less prone to instability, especially when navigating through uneven surfaces or when carrying heavy loads.

Key Benefits of Low Center of Gravity Casters

Enhanced Stability

The primary benefit of low center of gravity casters is enhanced stability. The lowered position of the wheel and load helps ensure that equipment remains grounded and less likely to tip over. This is particularly beneficial in high-stakes environments, such as medical equipment, material handling, or industrial machinery, where tipping could lead to accidents, downtime, or product damage.

Improved Load Handling

In high-capacity applications, such as warehouses or factories, low center of gravity casters can support heavier loads with ease. The optimized design allows the caster to handle more weight without compromising on maneuverability. This makes them an ideal choice for moving large machinery, heavy-duty carts, or industrial containers.

Reduced Risk of Accidents

The lower profile of these casters not only improves the load’s stability but also reduces the chances of accidents caused by rolling instability. By preventing the caster from tipping over easily, these wheels provide a safer working environment, especially in busy settings where operators need to move equipment quickly and efficiently.

Better Control and Maneuverability

Because low center of gravity casters are engineered for better balance, they also offer improved control during movement. This is particularly valuable in environments where precision is necessary, such as in laboratories, medical settings, or controlled manufacturing processes. The added stability reduces the chances of jerky movements and improves overall control.

Longer Service Life

By reducing the stress and strain on the caster wheel and components, low center of gravity casters can extend the service life of your equipment. The lower center of gravity helps to distribute the load more evenly, minimizing wear and tear and reducing the need for frequent repairs or replacements.

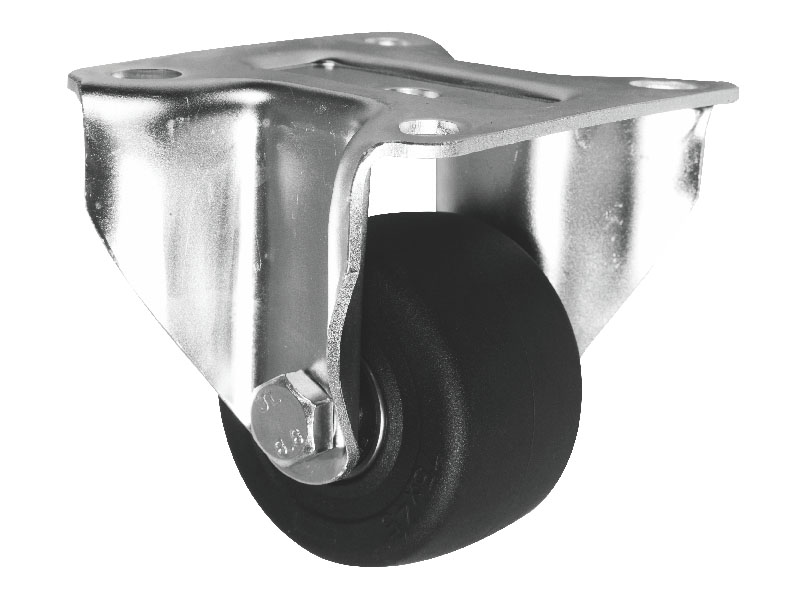

3 Inch Casters With 600Kg Loading

Ideal Applications for Low Center of Gravity Casters

Low center of gravity casters are highly versatile and can be used across various industries. Some of the most common applications include:

Medical Equipment

In the medical field, where stability and safety are paramount, low center of gravity casters are commonly used on hospital beds, surgical carts, and diagnostic equipment. The enhanced stability reduces the risk of tipping, ensuring that sensitive equipment can be moved with precision and care.

Material Handling

In warehouses and factories, low center of gravity casters are ideal for heavy-duty material handling carts and trolleys. These casters enable smooth movement of large, heavy items while ensuring the load stays balanced, even when navigating uneven floors or tight spaces.

Industrial Machinery

Manufacturers and production facilities benefit from low center of gravity casters on machinery and production line equipment. The enhanced stability and load-bearing capabilities reduce the risk of accidents and downtime, helping to keep operations running smoothly.

Foodservice and Hospitality

Low center of gravity casters are frequently used in foodservice carts, kitchen equipment, and service trolleys. These casters ensure that heavy items, such as food warmers and drink dispensers, remain stable while being transported throughout kitchens, dining areas, or event spaces.

Aerospace and Automotive

In the aerospace and automotive industries, equipment used for testing, maintenance, and assembly often requires high stability. Low center of gravity casters are employed on test rigs, mobile workstations, and component transport carts to ensure smooth and safe operation.

Swivel caster with alloy total brake

Factors to Consider When Choosing Low Center of Gravity Casters

Weight Capacity

Before selecting a low center of gravity caster, it’s important to assess the weight capacity required for your application. These casters are typically available in a range of load capacities, from light-duty options to heavy-duty models capable of supporting thousands of pounds. Ensuring that the caster matches the load specifications will maximize its stability and lifespan.

Wheel Material

The material of the caster wheel plays a significant role in its performance. For applications that require smooth movement on concrete or uneven floors, polyurethane wheels may be ideal due to their durability and ability to absorb shock. Rubber and steel wheels are also common options, depending on the nature of the environment.

Environmental Considerations

The environment in which the caster will be used will influence the type of material and design required. For instance, casters used in cleanroom environments may require specific materials to avoid contamination. Additionally, if the equipment will be used outdoors or in high-temperature conditions, corrosion-resistant casters are essential.

Mounting Options

Low center of gravity casters come in various mounting styles, such as swivel, rigid, or a combination of both. Depending on the application, you’ll need to choose a caster with the appropriate mounting configuration to allow for ease of movement and control.

Conclusion

Low center of gravity casters are an excellent solution for enhancing stability and safety in applications that require the reliable movement of heavy or delicate loads. Their design ensures better load distribution, reduces the risk of tipping, and offers greater control, making them ideal for high-stakes environments such as medical facilities, warehouses, and industrial settings.

When selecting low center of gravity casters, it’s essential to consider factors such as weight capacity, wheel material, environmental conditions, and mounting styles to ensure the optimal performance for your application.

By investing in high-quality low center of gravity casters, businesses can improve safety, efficiency, and equipment longevity, ultimately boosting productivity and reducing maintenance costs. For custom caster and wheel solutions tailored to your specific needs, explore Inford’s offerings to find the ideal caster solutions for your applications.