A Comprehensive Guide to Scaffolding Caster Wheels

Scaffolding Caster Wheels – In the bustling world of construction, scaffolding stands as the backbone, providing the necessary support for workers to reach great heights and execute their tasks seamlessly. An integral component that plays a critical role in this process is the scaffolding caster wheel. These wheels are not just a simple accessory but a key element that ensures the mobility and stability of the scaffolding system.

In this article, we delve into these unassuming scaffolding roller wheels, exploring their types, such as all-terrain scaffolding wheels, and heavy-duty scaffolding wheels, their applications, and the impact they have on the efficiency of construction projects.

Choosing the Right Scaffolding Caster Wheels

Scaffolding caster wheels come in various types, each designed to cater to specific needs and working conditions. Standard scaffold caster are the go-to for many projects, providing outstanding mobility. However, the diverse landscape of construction sites often demands a closer look at more robust specialized scaffolding roller wheels, like all-terrain scaffolding wheels and heavy-duty scaffolding wheels.

All-terrain scaffolding wheels are designed to meet the demands of challenging construction environments, providing enhanced mobility on uneven surfaces and navigating various obstacles with ease. These wheels are built to handle rough, unpredictable terrains, making them an excellent choice for construction projects that require flexibility and resilience in difficult conditions. Whether you’re working on a construction site with rugged ground or moving scaffolding across different terrains, these wheels ensure that the scaffolding can be maneuvered smoothly without the risk of getting stuck or damaged.

On the other hand, heavy-duty scaffolding wheels are specifically engineered to withstand the intense demands of large-scale construction projects. These caster scaffolding are designed for durability and strength, making them ideal for scenarios involving heavy loads or equipment. They are built to endure the daily wear and tear of demanding work environments, providing reliability and stability even under the most challenging conditions. Heavy-duty wheels are the perfect choice when the caster wheel scaffolding needs to support substantial weight, ensuring that the structure remains secure and functional throughout the project.

When selecting the right scaffolding wheels, it is important to consider several key factors to ensure optimal performance. One of the primary considerations is the load capacity of the castors for scaffolding, as it must be able to support the weight of the scaffolding and any materials or tools it is carrying. Additionally, the type of terrain the scaffolding will be navigating plays a significant role in the choice of wheel. For instance, all-terrain wheels are perfect for rough surfaces, while heavy-duty wheels are more suitable for construction sites with heavier loads. Another important factor is the presence of a locking mechanism, which ensures that the caster wheel scaffolding remains stable and secure when in place. Scaffolding wheels with locks are particularly valuable in preventing unwanted movement, ensuring safety and stability when the scaffolding is stationary. By carefully considering these factors, you can select the most appropriate scaffold caster that will provide both efficiency and safety on the job site.

All-terrain Scaffolding Wheels

Enhancing Mobility on Challenging Terrains

Construction sites are rarely smooth and even, often presenting challenges that demand more than just standard wheels. This is where all-terrain scaffolding wheels shine. These wheels come to the forefront in such situations, showcasing their ability to negotiate uneven surfaces with ease.

Gravel, debris, or rough patches – all-terrain scaffolding wheels ensure that the scaffolding moves effortlessly across challenging terrains, minimizing disruptions and delays, thus optimizing the efficiency of construction projects.

Furthermore, investing in all-terrain scaffolding wheels goes beyond immediate benefits. The increased mobility translates to enhanced productivity on construction sites, and the reduced strain on the entire scaffolding structure contributes to a longer lifespan.

About scaffolding wheels casters

Key Features:

-

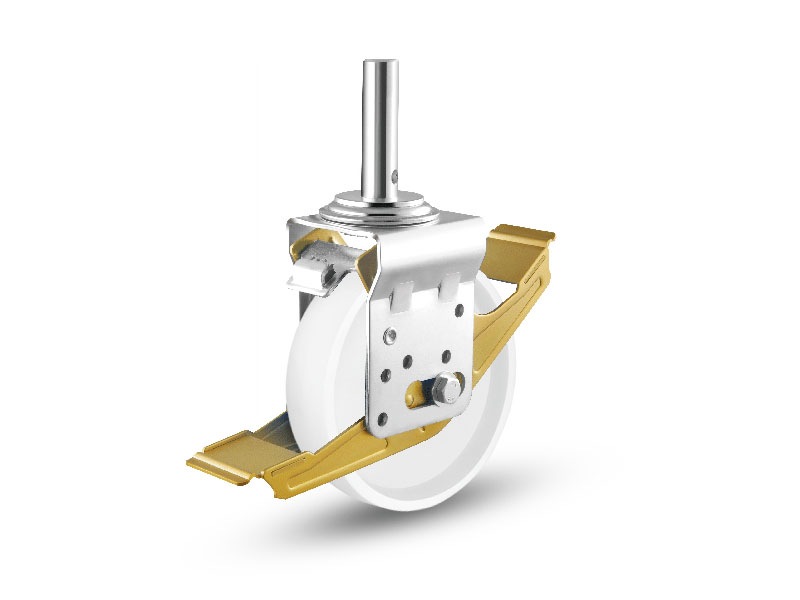

Material:

- Constructed from durable materials like nylon, polyurethane, or rubber to withstand heavy loads and rough surfaces.

- Some models feature metal frames for added strength.

-

Types:

- Fixed Casters: Provide straight-line movement.

- Swivel Casters: Allow 360-degree rotation for maneuverability in tight spaces.

-

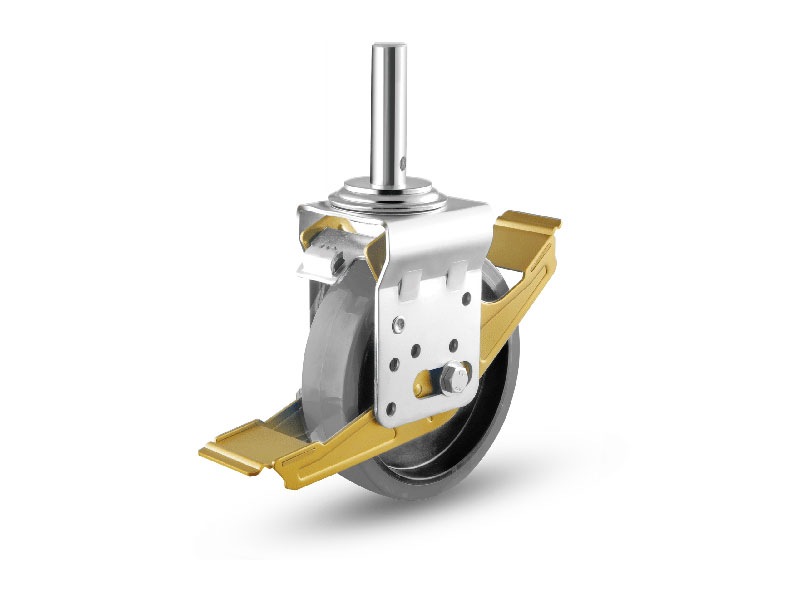

Braking Systems:

- Many casters include lockable brakes to secure the scaffolding when stationary, enhancing safety.

-

Load Capacity:

- Designed to support heavy loads, with capacities ranging from 100 kg to 500 kg per wheel, depending on the model.

Ensuring Safety with scaffolding wheels

Safety is paramount in any construction project, and scaffolding caster wheels play a vital role in maintaining a secure working environment. Particularly, scaffolding wheels with lock mechanisms are essential for preventing unintended movements to ensure the scaffold stays firmly in place.

Scaffolding wheels with locks offer a unique combination of durability, security, and ease of use, making them an essential component for construction projects that require both stability and flexibility. The locking mechanism is one of the key features of these wheels, designed to endure the rigors of heavy-duty construction work while providing reliable performance. The locks are made of high-quality materials that can withstand frequent use, ensuring that they remain functional and effective even in the toughest environments.

What sets scaffolding wheels with locks apart is the simplicity and efficiency with which the locking mechanism can be engaged or disengaged. This ease of use allows workers to quickly secure or release the scaffolding, ensuring that adjustments and movements can be made with minimal effort. When locked, these wheels provide a solid, stable platform for workers, offering peace of mind as they work at various heights. Whether workers are performing tasks such as painting, welding, or repairing structures, the secure positioning of the scaffolding ensures that the entire setup remains steady and safe, preventing any accidental shifts or tilting that could lead to falls or injuries.

Maximizing Efficiency with Heavy-duty Scaffolding Wheels

For construction projects that involve heavier loads or require extensive use of scaffolding, heavy-duty scaffolding wheels emerge as the preferred choice. These robust wheels are engineered to withstand intense weight and constant movement, offering the necessary support to ensure stability and reliability, even in the most demanding conditions. Whether dealing with bulky materials, equipment, or frequent relocation of scaffolding, these wheels provide the durability and performance needed to keep the project moving smoothly.

Constructed with high-quality materials that are built to endure the stresses of construction work, heavy-duty scaffolding wheels are designed for long-lasting resilience. Their tough construction, paired with impressive load-bearing capacities, makes them perfect for industrial and high-intensity construction sites. The durability of these wheels helps prevent the wear and tear commonly associated with heavy-duty tasks, offering extended service life and minimizing the need for frequent replacements. Over time, this durability can lead to significant cost savings in both maintenance and downtime, ensuring that your resources are used efficiently.

In addition to their strength and longevity, heavy-duty scaffolding wheels are also designed for compatibility with a broad range of scaffolding systems. This adaptability makes them a highly versatile solution, able to meet the varying needs of different construction projects. Whether you’re constructing a towering skyscraper, working on a bridge, or carrying out residential building work, these scaffolding on wheels provide the stability, safety, and dependability necessary for your scaffold systems to function at their best. By choosing heavy-duty scaffolding wheels, you’re investing in a solution that enhances both the efficiency and safety of your project, ensuring that it can meet the demands of even the most challenging environments.

Conclusion of Scaffolding Caster Wheel

The different kinds of scaffolding caster wheels each have a special job in the complex process of building things. Whether it’s the regular type, the all-terrain type for rough grounds, or the heavy-duty type for big jobs, choosing the right wheels for scaffolding can make a big difference in how quickly and safely you can get your project done.

As construction keeps changing and improving, these scaffolding roller wheels– which people often don’t think about much – become more and more important. They help us build the structures we build to reach new heights safely and seamlessly.

1. What are scaffolding caster wheels used for?

Scaffolding caster wheels are used to provide mobility and ease of movement for scaffolding systems. They are attached to the base or legs of scaffolding to allow workers to move the structure across the job site, facilitating quick adjustments and repositioning. This helps improve efficiency and safety, as the scaffolding can be easily relocated without the need for heavy lifting or dragging.

scaffold caster wheel

2. How do I choose the right caster wheels for scaffolding for my project?

When selecting scaffolding caster wheels, it’s essential to consider factors such as the weight capacity, terrain type, and whether a locking mechanism is needed. Heavy-duty caster wheels are ideal for handling heavier loads, while all-terrain wheels are better suited for uneven or rough surfaces. Additionally, casters with locks provide extra security and stability, particularly when working at height.

3. How do scaffolding caster wheels with locks enhance safety?

Scaffolding caster wheels with locks ensure stability by securely holding the scaffolding in place once it has been positioned. The locking mechanism prevents unwanted movement, offering a solid, safe platform for workers to operate from. This is especially crucial when working at elevated heights, where any accidental shifts could pose significant safety risks. The ease of locking and unlocking further adds to the efficiency of the setup.